Mowi choose

Maritech Eye™

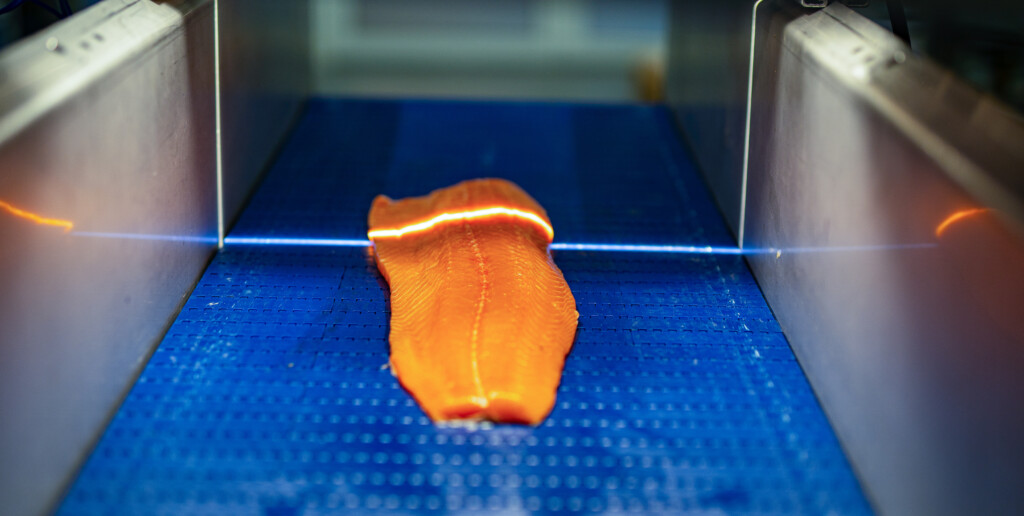

We are pleased to announce that Mowi Consumer Products UK has implemented Maritech Eye™ to further enhance the quality assessment of their Mowi brand smoked salmon.

Automated, objective quality control and documentation

Beginning in 2018, Mowi, Maritech, and Nofima have cooperated in a joint innovation project to develop a technology for real-time quality scanning of salmon fillets at industrial speed. The project was successful, and Maritech Eye™ was launched for redfish at Aqua Nor in August 2021.

Maritech Eye™ advanced algorithms and hyperspectral camera solution detects and documents blemishes within the fillets and the size location of these quality challenges. This quality assessment method is the only one of its kind in the world, it is done at industrial speed, and live data is provided to operators and management.

After the end of the innovation project, Mowi Consumer Products UK and Maritech co-operated closely in a short pilot period to establish the quality criteria and make the necessary adjustments to integrate Maritech Eye™ within the production environment.

“For our business here in the UK and in particular the Mowi brand, this gives us the ability to pre-select fillets based on a specification to reduce the manual intervention of removing blemishes once the fillets have been sliced. Furthermore, sorting by quality and providing objective information gives us the ability to allocate the material accordingly and allows us to utilise our resources more efficiently and effectively” says Gary Paterson, Head of Operations, Mowi CP UK.

Ready for the global market

“Mowi is one of the most innovative seafood companies in the global seafood industry, and we are proud that they chose Maritech Eye™” says Per Alfred Holte, VP Technical Solutions in Maritech.

“Mowi Consumer Products UK is one of three international Maritech Eye™ redfish projects this fall, and we are impressed by how the Mowi team has handled the development and implementation in a period when it still has been difficult to travel due to Covid 19. Our team has only been at the site in Scotland once this year since the initial physical installation of the equipment.”

“Together we have proved that most of the optimization and implementation process can be done remotely and that Maritech Eye™ is ready for the global seafood industry, even during a pandemic.”

Would you like to know more?

We would love to talk to you.